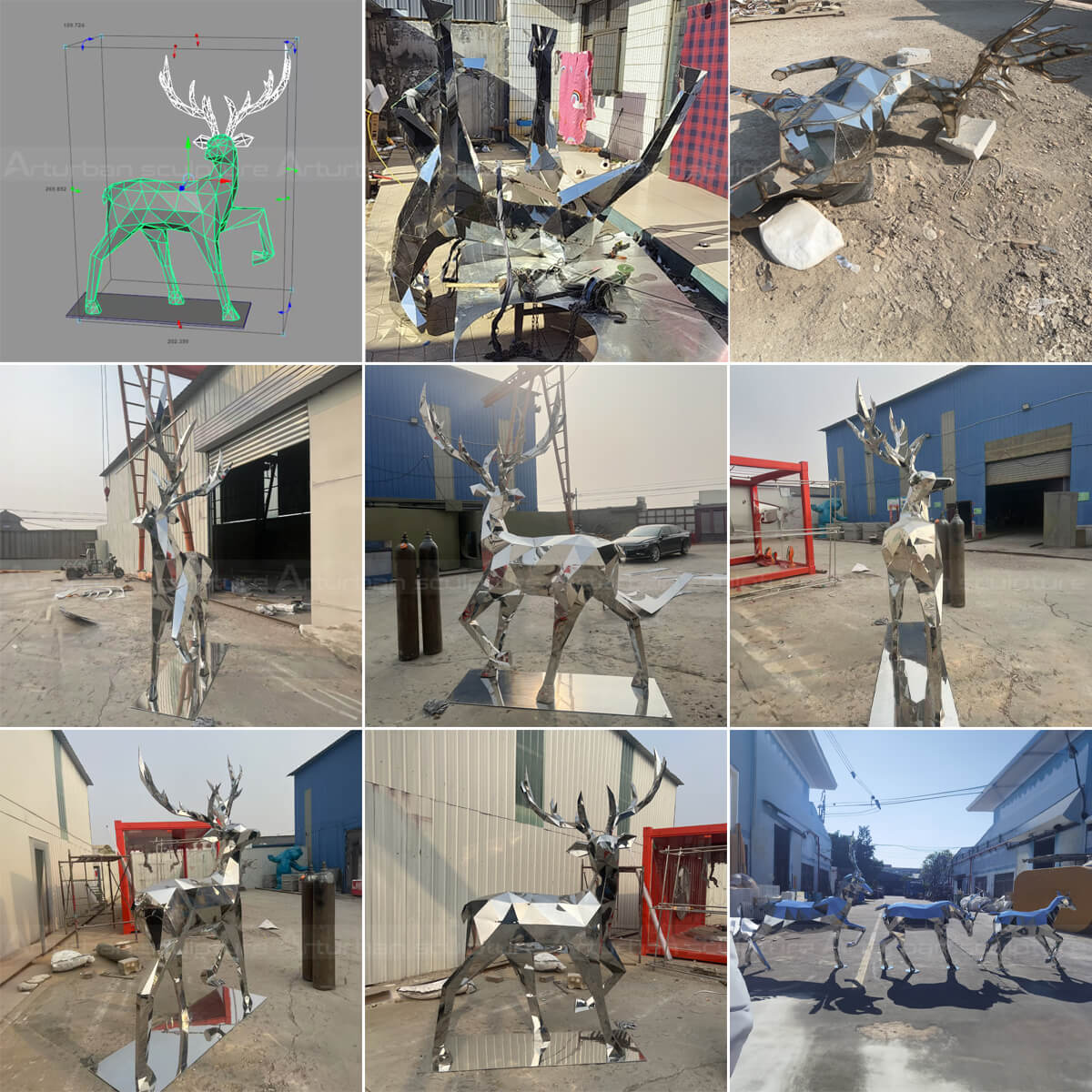

1. Introduction of Deer Metal Sculpture

This low-poly stainless steel deer sculpture showcases the elegance of modern art through bold geometric design. The form of the Deer Metal Sculpture is composed of simplified geometric surfaces and broken lines, and the deer’s body and posture are condensed into a simple and powerful shape, which is very modern. The deer’s head is slightly tilted, and its eyes are alert, as if observing the surrounding environment, and its front legs are gently raised, full of dynamics. This geometric treatment not only makes the sculpture have the form of natural creatures, but also integrates the expression of abstract art.

The Deer Metal Sculpture is made of mirror stainless steel, which has a smooth surface and reflects light. It can interact with the surrounding environment and show different visual effects as the light changes, which enhances the dynamic and layered sense of the sculpture. The combination of its low-polygon style and mirror stainless steel makes it an ideal choice for contemporary public art and interior decoration. Whether it is placed in a commercial center, a modern garden, or a private courtyard, it can become an eye-catching artistic focus. Arturban Sculpture can customize various geometric animal statues. Welcome to contact us for more details.

2. Production process of Deer Metal Sculpture

- Design Communication: Client provides reference images and dimensions. We confirm the concept and requirements.

- 3D Modeling: Create a 3D digital model to visualize size, shape, and structure.

- Mold Confirmation: Produce a full-size foam or clay mold. Photos are sent for client approval, and details can be adjusted.

- Sheet Cutting & Forging: Cut stainless steel sheets and forge each geometric panel as per design.

- Welding: Assemble and weld all components to form the full sculpture.

- Polishing & Coloring: Polish the surface to a mirror finish.

- Final Inspection: Check proportions, structure, and finish to ensure quality.

- Packaging: Use reinforced wooden crates with shockproof foam for safe transportation.

- Shipping: Arrange global delivery by sea or air as requested.

Send us your requirements now, we will reply to your email within 24 hours